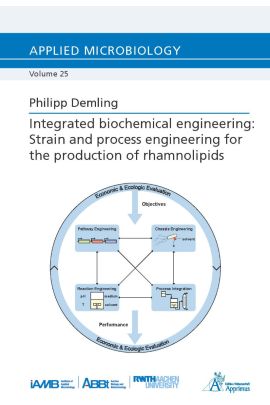

Establishing biotechnological processes within the envisaged circular bioeconomy requires holistic approaches, including integration of all stages of process development. The presented thesis illustrates the integration of strain and process engineering using the example of producing the biosurfactant rhamnolipids with recombinant Pseudomonas putida KT2440.

When producing biosurfactants in aerated bioreactors, excessive foaming is process-hindering. To mitigate this challenge, an in situ liquid-liquid extraction was established by selecting a suitable, biocompatible extraction solvent in a multi-step strategy. Unraveling interactions of integrated up- and downstream processing resulted in the definition of a joint operational window for cultivation and extraction. Thereby, a foam-free fed-batch cultivation of rhamnolipid-producing P. putida KT2440 with integrated in situ extraction was established. Subsequently, different cultivation modes have been evaluated for enhanced production, and strategies for improved phase separation have been explored.

Host engineering was approached to further enhance the solvent tolerance of P. putida KT2440, thereby enabling the utilization of additional extraction solvents. P. putida KT2440 was adapted to tolerate 1-octanol, and reconstruction of tolerant strains enabled the production of rhamnolipids in the presence of 1 octanol. Another challenge is transient oxygen limitations in industrial fermentations, which P. putida KT2440 masters well without losing production capacity, highlighting its outstanding suitability for industrial-scale production processes.

Previous findings were applied to define an operational window to produce rhamnolipids with recombinant P. putida KT2440 in a custom-designed multiphase loop reactor, integrating cultivation and an in situ counter-current liquid-liquid extraction. Performance indicators compared well with two-liquid phase cultivations in stirred-tank reactors, emphasizing the robustness of P. putida KT2440 and serving as a proof of concept for the novel reactor type.

In conclusion, this thesis advocates integrated and interdisciplinary bioprocessing. While the specific outcomes of this thesis are related to the presented system, basic concepts can be extrapolated to other challenging cases in bioprocess development. Thereby, competitive industrial bioprocesses are promoted, contributing to establish the envisaged circular bioeconomy.

| Autor | Demling, Philipp |

|---|---|

| Gewicht | 0.344 kg |

| Erscheinungsdatum | 06.12.2021 |

Institut für Angewandte Mikrobiologie (iAMB)

Integrated biochemical engineering: Strain and process engineering for the production of rhamnolipids

Kurzbeschreibung

Establishing biotechnological processes within the envisaged circular bioeconomy requires the integration of all stages of process development. In this context, a joint operational window for the microbial production and in situ extraction of rhamnolipids in a novel multiphase loop reactor was defined. While outcomes of this thesis are related to the presented system, interdisciplinary approaches can be transferred to other bioprocesses, advocating the transition to a sustainable bioeconomy.